Earlier this month, Gilbane Building Co. proposed that the Occupational Safety and Health Administration (OSHA) should require construction workers to wear safety harnesses whenever they are working at a height of 6 feet or more above a lower level. This requirement is part of Gilbane’s safety program, which they claim has prevented 20 potential fatalities since 2011. It’s hard to argue with a company that has won multiple industry safety awards with a safety program that has resulted in 95% of projects completed having zero lost time injuries and 80% of projects finished with zero recordable injuries in 2015.

Safety Harnesses & Fall Protection According to OSHA

Currently, OSHA requires that employers provide fall protection for construction workers on a walking or working surface with an unprotected edge that is 6 feet or more above a lower level. Fall protection approved by OSHA includes guardrails, safety net systems, and personal fall arrest systems (i.e. safety harnesses). Employers are permitted to use any or all of the three prescribed fall protection systems in most instances, not specifically safety harnesses as Gilbane recommends.

The rule covers a number of areas and activities where fall protection is required and the fall protection systems allowed. For example, protecting workers from falls into holes, such as skylights, another acceptable means of fall protection is installing a cover over the opening. When working on the face of reinforcing steel or formwork above 6 feet, employees can use a personal fall arrest system, safety net, or positioning device system.

The rules are also different when it comes to working on scaffolding and for steelworkers. For scaffold work, employees must have fall protection when working at a height of 10 feet or more above a lower level. The type of fall protection required by OSHA varies depending on the type of scaffold being used. A ladder jack scaffold or a float scaffold requires a personal fall arrest system (aka: safety harness) while a single-point or two-point adjustable suspension scaffold requires both a safety harness and a guardrail system.

Workers performing steel erection work aren’t required to use fall protection until they are working at heights of 15 feet or more above a lower level. Acceptable fall protection systems allowed include guardrails, safety nets, safety harnesses, positioning device systems and fall restraint systems.

OSHA has not responded to Gilbane’s safety harness proposal and doesn’t have any proposed rulemaking currently to make any changes to their fall protection standards. OSHA’s reasoning for having different height thresholds for fall protection for different aspects of construction such as scaffold work and steel erection was cited as being in line with consensus standards at the time and with the difficulty for deploying fall protection at the 6-foot threshold for these activities.

Worker Deaths From Falls

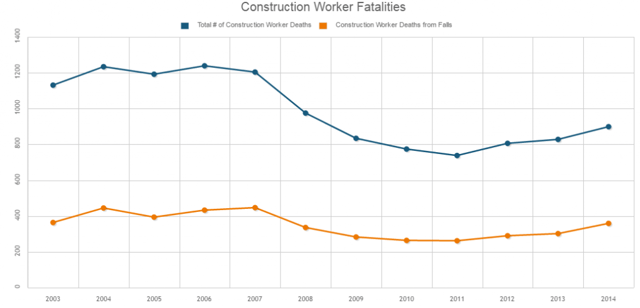

Judging by the increasing number of construction worker fatalities over the past several years, it might not be a bad idea for OSHA to update their current rules regarding fall protection in construction. Worker deaths as a result of falls increased 37% between 2011 and 2014. The total number of construction worker deaths increased by 21.8% during that same time.

359 of the 899 construction worker deaths in 2014 were caused by falls - 40% of all construction fatalities. There were 4,821 workplace fatalities in 2014 and construction accounted for 18.6% of all worker deaths, the highest for any industry. Take a look at OSHA’s most cited standards for construction firms and it’s no surprise why fatalities from falls continue to climb each year. Six of the top 10 all had to do with working at height. The top four have held their spots for a number of years now and cover fall protection, scaffolds, and ladders.

The makeup of the construction workforce is drastically different from what it was just a decade ago. Many highly skilled and experienced workers left the industry when the recession hit and never came back when things started improving. This left employers having to fill positions with less experienced workers. As construction activity continues to increase, the focus on safety needs to be at the forefront of every company. According to the numbers, the inclusion of safety harnesses should be seriously considered.

When creating a safety program for your construction company, your policies, procedures, and protocols shouldn't be a mirror image of OSHA's construction industry standards. Abiding by OSHA rules should be the bare minimum and just doing the bare minimum is no way to create a culture of safety. You need to create a culture where every employee of the company strives toward a goal of zero accidents on every project. For more information, be sure to check out our 8 Tips to Building a Stellar Safety Program.

About Kendall Jones

Kendall Jones is the Editor in Chief at ConstructConnect. He has been writing about the construction industry for years, covering a wide range of topics from safety and technology to industry news and operating insights.

Sign In

Sign In